Creative Concrete Coatings

Repair, Resurface, and Renew

WHY WE LOVE OVERLAYS?

Benefits & Features

Affordable & Sustainable

Resurfacing and overlay systems are a cost-effective solution in comparison to the expense of removing and replacing the concrete entirely. Furthermore, it is an environmentally conscious option as it minimizes concrete waste and utilizes less material leaving a smaller carbon footprint.

Boost Property Value

A concrete overlay is a custom feature that will improve the look and feel of your property adding to its marketability and value, providing a potential return on your investment.

Stain Resistant & Low Maintenance

Overlays are sealed surfaces that exhibit resistance to staining and require minimal maintenance. Routine cleaning involves sweeping, blowing, or hosing off debris. For more stubborn stains, utilize a mild detergent and gentle scrubbing technique, followed by a thorough rinse. Periodic reapplication of a high-quality sealer is advised to restore the surface's luster and water-repellent properties.

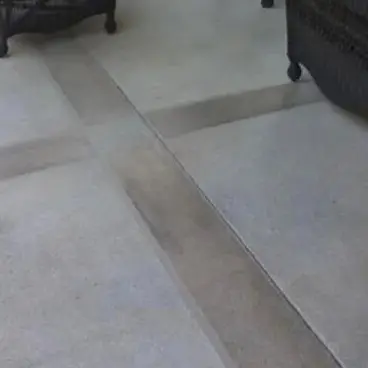

Improved Aesthetics & Embody Your Style

Damaged, ugly, stained, and or worn concrete can be a real eye sore, and take away from a property's overall appearance. Resurfacing with an overlay will provide beautiful new surface adding style and sophistication to your property.

Versatility

Our overlay system is extremally versatile and can be used for many different applications and repairs such as flooring, countertops, retaining walls, and brick repair. Choose from an almost unlimited array of colors and design options.

Textured, Slip Resistant Surfaces.

We offer many styles and textures to choose from allowing us to achieve your desired degree of slip resistance. A perfect option for a pool deck. We also incorporate a non-slip additive in our final seal coat to help prevent any falls.

CONNECT WITH YOUR STYLE

Design & Finishing Options

WHAT YOU CAN EXPECT

Pre-Installation Process

Discovery

& Site Visit

Discovery is usually a quick phone call where we will discuss your project to determine if we would be a good fit and an adequate budget exist. During the initial site visit, we will evaluate the condition of the existing concrete, take measurements, explore design possibilities, and discuss your vision and budget for the project.

Design

& Planning

Upon acceptance of the proposed estimate we will begin to work with you to design and customize your project (colors, patterns, and texture), create sample boards or mock-ups for your approval, and begin the procurement of materials and supplies.

Schedule

Resources

After all materials and supplies have been obtained, we will coordinate with clients to establish a good start date, review the project plans/time frame, and communicate any client responsibilities (ex. clear any furniture from work site).

Install

Process

Every installation begins with a through preparation of the substrate, repair and treatment of any imperfections or cracks, followed with application of the overlay, staining/coloring as specified, and protected with the choosen sealer to finish it off.

RESURFACING / OVERLAY

Installation Process

Prep

Every job begins with a thorough surface preparation, paying special attention to remove all dirt, debris, and oil to promote proper bonding. In addition to the thorough cleaning, we will make sure that the substrate is properly profiled to deliver the very best end results and durability.

Repair

Prior to resurfacing, we will inspect and repair any surface imperfections including cracks, spalling, latency, or other cosmetic issues to promote an ideal substrate foundation for the overlay to adhere to.

Resurface

Once all repairs have been made and the surface is ready to be resurfaced, we will install the polymer modified concrete utilizing a variety of techniques to achieve the desired finish.

Enhance

Following the resurfacing, we will begin stain, dying, or working on custom enhancements to create the chosen look. During this phase other enhancements such as hand scoring or custom logos will be installed.

Protect

The final step, which is to apply 2 coats of a high-quality concrete sealer, in the desired sheen, to add durability, stain resistance, and protect the surface. Slip resistant additives are recommended in any environment or area where slip and falls might be of concern.

FREQUENTLY ASKED QUESTIONS

FAQ

Our concrete overlays in almost all circumstances last 10-15 years, but can last 25+ years with attentive care and regular maintenance. The condition of the underlying concrete surface is another factor that affects product durability: we prepare the underlying concrete surface as best we can to maximize durability and performance.

Care and maintenance are relatively simple and infrequent. Sweep surfaces as needed to avoid dirt and debris buildup. Wash surfaces annually with water and a mild detergent: scrub gently with a medium bristle deck brush and hose off. Exterior concrete overlay surfaces can also be pressure washed. We recommend a resealing treatment every 3-6 years to maximize product life.

There are almost unlimited combinations of colors, patterns, and finishes available for concrete overlays. Our staff is experienced in helping homeowners understand how combinations not only complement each other but align with individual home styles. We have a full selection of sample boards, and our team can discuss and compare options, so you can make a confident decision about the best look for your home.

Concrete resurfacing cost typically range from $8-$17 per square foot depending on the design and complexity of the finish. Other factors to consider when evaluating cost are the condition of the existing concrete, if there are any repairs required prior to resurfacing, if there are any existing coatings that will need to be removed, and the project location. Each job is evaluated on these factors in order to determine the estimated cost. Contact us to talk more about your project and about what you could expect the cost to be.

Ready to Get Your Project Started?

Click the button to the right, fill out the form, and we will have one of our project managers reach out to you.